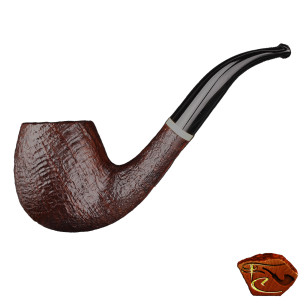

sandblasted finish

Sandblasted pipes: a finish that enhances the wood's structure

Sandblasted finishing is one of the traditional techniques used to treat briar in the pipe world. It consists of highlighting the wood's natural grain by removing its softer parts using a high-pressure abrasive. This process reveals the briar's grain in an authentic way, without modifying it artificially.

Often chosen for blocks with a straight or regular grain, sandblasted finishing is also appreciated for its ability to discreetly conceal certain minor surface defects, without compromising the overall quality of the pipe. It gives rise to pieces with subtle or more pronounced relief, depending on the depth of the work and the nature of the wood.

Dunhill first introduced this finish in 1917 with its famous Shell Briar series. The process, patented the following year, consisted of immersing the pipe-heads in a heated oil bath, followed by sandblasting to bring out the grain. This method made it possible to enhance briars whose appearance was not suited to a smooth finish, given the demanding nature of the brand, by giving them a distinctive texture and visual character. The technique quickly became a reference in the pipe world, to the detriment of the oil bath.

In addition to its visual appeal, this finish offers a pleasant grip. It represents a well-balanced alternative between aesthetics, functionality and affordability.

Sandblasted finish: natural grain enhancement

Sandblasting involves projecting a fine abrasive (usually sand or silica) at high pressure onto the surface of the briar. This operation removes the softer parts of the wood while leaving the denser areas intact, bringing out the wood's natural grain and veining. Unlike rustication, sandblasting does not create an artificial pattern, but highlights the briar's true structure.

This treatment is often reserved for blocks with straight or well-oriented grain, as it reveals an aesthetic relief that is particularly appreciated. Sandblasting is also used when the briar has slight surface defects, such as sandpits. These small natural cavities are the result of mineral inclusions or discontinuities formed during the heather's underground growth. Rather than removing these heads, workshops opt for sandblasting, which visually attenuates these irregularities while enhancing the wood grain.

Some sandblasted finishes leave the bowl top or edges smooth for contrast, while others are uniformly sandblasted.

Sandblasting depth varies according to workshop and series : some pipes have a slight, discreet relief, while others have a more pronounced grain, offering an almost sculpted texture. This diversity reflects both the type of briar used and the maker's aesthetic choices.

In addition to visual appeal, sandblasting offers a number of practical advantages. The textured surface promotes heat dissipation, which can improve comfort in the hand when smoking. What's more, although sandblasting removes a thin layer of material, the variation in weight between a sandblasted pipe and a smooth pipe of the same format is generally marginal. The weight depends more on the natural density of the briar used and its degree of drying at the time of turning.

Last but not least, sandblasted pipes offer access to beautiful briars at a more reasonable cost than premium smooth finishes. This makes them a popular option for enthusiasts attached to both the authenticity of the material and the functionality of their pipe.